2023 Ford F-150 Manual: A Comprehensive Overview

The 2023 Ford F-150 manual presents a unique driving experience, blending robust capability with a traditional gearbox, appealing to enthusiasts seeking control.

The 2023 Ford F-150 manual represents a deliberate return to driver engagement, offering a distinct alternative within a market increasingly dominated by automatic transmissions. This configuration caters to a niche audience – those who appreciate the tactile connection and control afforded by a traditional stick shift. While not widely publicized, the availability of a manual transmission in the F-150 signifies Ford’s acknowledgement of enthusiast demand.

This guide provides a comprehensive exploration of the 2023 F-150 manual, covering everything from trim level availability and key features to detailed mechanical specifications and practical maintenance advice. We will delve into the driving experience, performance characteristics, and potential limitations associated with this unique offering. Understanding the nuances of this transmission is crucial for maximizing its potential and ensuring long-term reliability.

Understanding Trim Levels & Manual Availability

The availability of the manual transmission in the 2023 Ford F-150 is strategically limited, focusing on specific trim levels to maintain a focused offering. Typically, the manual option is found on the base XL trim, appealing to buyers prioritizing functionality and cost-effectiveness over luxury features. Higher trims, such as XLT, Lariat, and beyond, generally do not offer a manual transmission choice.

This restriction allows Ford to streamline production and cater to the core demographic seeking a manual F-150. Engine choices paired with the manual transmission are also limited, usually to the base engine option; Prospective buyers must carefully consider these constraints when configuring their vehicle, ensuring the desired trim and features align with manual availability.

Key Features of the 2023 F-150 Manual Transmission

The 2023 Ford F-150’s manual transmission is a robust, six-speed unit designed for durability and driver engagement. It features a heavy-duty clutch system built to withstand the demands of truck usage, including towing and hauling. The gear ratios are optimized for both on-road cruising and off-road capability, providing a balance of power and efficiency.

A key feature is the transmission’s direct mechanical connection, offering a more tactile driving experience compared to automatics. While lacking the advanced features of some modern manual transmissions, it prioritizes simplicity and reliability. The shift linkage is designed for precise and confident gear changes, enhancing driver control and enjoyment.

Driving & Performance

The 2023 F-150 manual delivers a raw, connected driving feel, emphasizing driver control and engagement through precise shifting and responsive power delivery.

Manual Transmission Operation: Shifting & Clutch Control

Operating the 2023 F-150’s manual transmission requires mastering smooth clutch engagement and precise gear selection. The clutch pedal offers a defined engagement point, crucial for seamless shifts. Downshifting necessitates rev-matching to maintain vehicle stability and prevent jarring transitions.

Drivers should fully depress the clutch during gear changes and avoid riding the clutch, which causes premature wear. The gear lever provides a direct and tactile feel, allowing for confident selection of the six available speeds. Proper technique involves coordinating clutch release with throttle application for optimal acceleration and control. Learning the transmission’s characteristics is key to maximizing driving enjoyment and efficiency.

Performance Characteristics: Acceleration & Fuel Economy

The 2023 F-150 manual delivers a responsive driving experience, though acceleration figures may slightly differ compared to automatic variants. Expect a robust low-end torque, providing ample power for daily driving and hauling. Precise gear selection allows drivers to optimize engine output for various conditions.

Fuel economy is influenced by driving style; conservative shifting and maintaining appropriate speeds yield better results. While official EPA estimates vary based on engine and configuration, the manual transmission encourages mindful driving, potentially improving overall efficiency. The engaging nature of the manual gearbox often leads to a more connected and controlled driving experience, enhancing performance perception.

Towing & Payload Capacity with Manual Transmission

The 2023 F-150 manual maintains impressive towing and payload capabilities, comparable to its automatic counterparts when properly equipped. Maximum towing capacity reaches substantial figures, dependent on engine choice, cab configuration, and axle ratio. Careful gear selection is crucial for managing weight during towing, providing enhanced control and stability.

Payload capacity remains competitive, allowing for significant cargo hauling. Drivers benefit from the manual transmission’s ability to precisely manage engine braking on descents, improving safety while towing. Proper weight distribution and adherence to Ford’s towing guidelines are essential for maximizing performance and ensuring a secure towing experience.

Mechanical & Technical Details

The 2023 F-150 manual features a robust powertrain, specifically engineered components, and a carefully calibrated transmission for optimal performance and durability.

Engine Specifications Compatible with Manual Transmission

For the 2023 model year, Ford strategically paired the manual transmission option with the 5.0-liter Ti-VCT V8 engine, delivering a compelling blend of power and driver engagement. This naturally aspirated engine boasts 400 horsepower and 410 lb-ft of torque, providing ample capability for both daily driving and demanding tasks. The engine’s robust construction ensures reliability, while its responsive nature complements the direct control offered by the manual gearbox.

Notably, the 3.5L EcoBoost and other engine options were not offered with a manual transmission in 2023. This focused approach allowed Ford to fine-tune the V8 and manual pairing for an optimized experience. The engine utilizes features like independent variable cam timing to maximize efficiency and performance across the rev range, making it a suitable choice for various driving conditions and workloads.

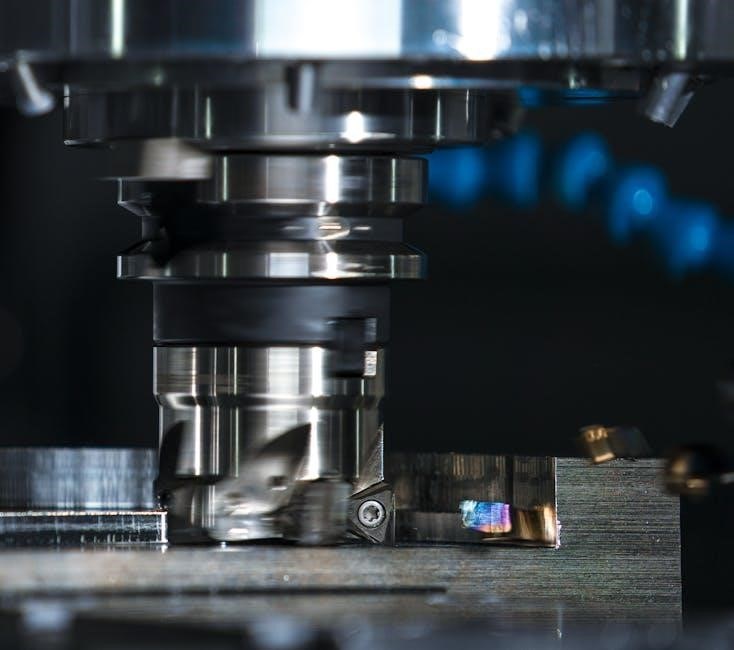

Transmission Details: Gear Ratios & Components

The 2023 Ford F-150’s manual transmission is a robust, heavy-duty six-speed unit designed to handle the V8 engine’s substantial torque output. Its gear ratios are carefully calibrated to provide a balance between acceleration, towing capability, and fuel efficiency. First gear is geared relatively low for strong off-the-line performance and tackling challenging terrain, while higher gears are optimized for highway cruising.

Key components include a durable synchronizer package for smooth shifting, and reinforced gears constructed from high-strength alloys. The transmission features a twin-disc clutch assembly, enhancing durability and providing a firm pedal feel. This setup ensures reliable operation even under heavy loads. The shift linkage is designed for precise and direct engagement, contributing to a connected driving experience.

Maintenance Schedule for Manual Transmission

Maintaining the 2023 Ford F-150’s manual transmission is crucial for longevity and optimal performance. Ford recommends a fluid change every 60,000 miles, or 5 years, whichever comes first, using a specifically formulated manual transmission fluid. Regular inspections of the shift linkage and clutch hydraulics are advised every 30,000 miles to ensure smooth operation.

Clutch wear should be monitored, with replacement typically needed between 75,000 and 150,000 miles depending on driving conditions. Inspecting the clutch master and slave cylinders for leaks is also vital. Periodic checks of the transmission mount for damage or wear are recommended. Following this schedule will help prevent costly repairs and ensure a reliable driving experience for years to come.

Interior & Technology

The 2023 F-150 manual boasts a modern cabin with user-friendly tech, including infotainment systems and connectivity features, enhancing the driving experience.

Interior Features & Comfort

The 2023 Ford F-150 manual’s interior prioritizes both durability and comfort, catering to demanding work and relaxed journeys. Cloth or leather upholstery options are available, alongside supportive seating designed for long hours behind the wheel.

Higher trim levels introduce premium materials and enhanced features like heated and ventilated front seats, and power-adjustable pedals. The cabin layout is thoughtfully designed, offering ample storage solutions for tools and personal belongings.

Noise, vibration, and harshness (NVH) levels are well-controlled, contributing to a quieter and more refined ride. The spacious cabin provides generous headroom and legroom for all occupants, ensuring a comfortable experience even on extended trips.

Infotainment System & Compatibility

The 2023 Ford F-150 manual features Ford’s SYNC 4 infotainment system, offering a responsive touchscreen interface and intuitive controls; Standard features include Apple CarPlay and Android Auto compatibility, enabling seamless smartphone integration for navigation, music, and communication.

Available upgrades encompass a larger touchscreen display, integrated navigation, and a premium B&O sound system for an immersive audio experience. Wireless connectivity options are also present on select trims, simplifying device pairing.

FordPass Connect provides remote vehicle access via a smartphone app, allowing owners to lock/unlock doors, start the engine, and check vehicle status. Multiple USB ports and a 12V power outlet ensure ample charging options for passengers.

Safety & Driver Assistance

The 2023 F-150 manual incorporates Ford Co-Pilot360, offering features like automatic emergency braking, lane-keeping assist, and blind-spot monitoring for safety.

Safety Features & Ratings

The 2023 Ford F-150, even in manual transmission guise, doesn’t compromise on safety. Standard features include a comprehensive airbag system, anti-lock brakes, and electronic stability control. Ford’s Co-Pilot360 suite is typically included, offering functionalities like Pre-Collision Assist with Emergency Braking, Lane-Keeping System, and a Blind Spot Information System (BLIS).

These technologies actively work to prevent accidents and enhance driver awareness. While specific crash test ratings may vary depending on configuration, the F-150 generally receives high marks from both the National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute for Highway Safety (IIHS). The robust construction of the F-150 frame contributes significantly to occupant protection in the event of a collision.

Driver-Assistance Technologies

The 2023 Ford F-150 manual benefits from a range of driver-assistance technologies designed to enhance safety and convenience. Ford Co-Pilot360, often standard, includes features like Adaptive Cruise Control, which maintains a set distance from the vehicle ahead, and Evasive Steering Assist, helping to avoid collisions.

Lane-Keeping Assist and Lane Departure Warning provide alerts and gentle steering assistance to keep the truck within its lane. Automatic Emergency Braking detects potential forward collisions and applies the brakes if the driver doesn’t respond. Other available technologies include a 360-degree camera system for easier maneuvering and Pro Trailer Backup Assist, simplifying trailer towing. These systems work seamlessly, even with the manual transmission.

Troubleshooting & Common Issues

Clutch wear, shifting difficulties, and occasional stalling may occur in the 2023 F-150 manual; proper driving technique minimizes these potential problems.

Common Problems with the 2023 F-150 Manual

Several issues have been reported by owners of the 2023 Ford F-150 manual transmission. A frequent complaint centers around clutch engagement, with some drivers experiencing a high clutch pedal or difficulty finding the friction point, potentially leading to stalling, especially on inclines.

Rough shifting, particularly between first and second gear, is another common concern, often attributed to synchronization issues within the transmission. Some owners have noted unusual noises emanating from the gearbox during shifts.

Premature clutch wear is also a potential problem, influenced heavily by driving habits and towing frequency. Finally, occasional reports surface regarding the throw-out bearing failing, resulting in a persistent squealing sound when the clutch pedal is depressed. Regular maintenance and careful driving can mitigate these concerns.

DIY Maintenance & Repair Tips

For the 2023 Ford F-150 manual, regular fluid checks are crucial; use the Ford-specified manual transmission fluid. Inspect the clutch cable for fraying or damage, adjusting it as needed for optimal pedal feel. Listen for unusual noises during shifts, indicating potential synchronization issues.

When towing, avoid aggressive clutch engagement to prevent premature wear. Periodically check the throw-out bearing for signs of squealing, a precursor to failure. Simple tasks like cleaning and lubricating shift linkages can improve shifting smoothness.

However, complex repairs like clutch replacement or transmission disassembly should be left to qualified mechanics. Always consult the official Ford service manual for torque specifications and procedures.

Resources & Further Information

Access official Ford owner manuals and online forums for detailed specifications, troubleshooting guides, and community insights regarding the 2023 F-150 manual.

Official Ford Resources & Manual Downloads

Ford provides a wealth of resources for 2023 F-150 manual owners directly through their official website. Owners can access the complete owner’s manual in digital format, offering detailed information on vehicle operation, maintenance schedules, and safety features. Ford’s website also features a dedicated support section with frequently asked questions, troubleshooting guides, and how-to videos.

Furthermore, the FordPass app offers convenient access to vehicle information, service scheduling, and roadside assistance. For downloadable manuals, navigate to the Ford Owner Guide portal, where you can search specifically for the 2023 F-150 manual transmission variant. These resources ensure owners have readily available support for maximizing their driving experience and maintaining their vehicle’s performance.